edelook.com

edelook.com

HPF8036R Frame Plate Liner

Shijiazhuang Heavy Pump Company Limited 2

Summary Description

1)Model: HPF8036R Frame Plate Liner

2)For slurry pump: 150HS-G Slurry Pump

3)Material: natural rubber

4)Weight: 26.00kg

$670.00

PRODUCT DETAILS

| Product description |

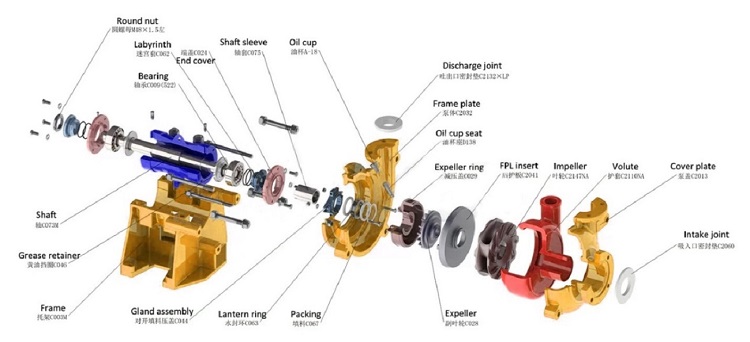

The metal casing of a slurry pump is an essential component of the pump, serving as a protective shell that encloses the internal parts of the pump. It is designed to withstand the abrasive and corrosive nature of the slurry being pumped, which typically contains high concentrations of solids and may be chemically aggressive.

The metal casing of a slurry pump is an essential component of the pump, serving as a protective shell that encloses the internal parts of the pump. It is designed to withstand the abrasive and corrosive nature of the slurry being pumped, which typically contains high concentrations of solids and may be chemically aggressive.

The metal casing of a slurry pump can be made from various materials, with high chromium metal alloy being a common choice due to its excellent wear and corrosion resistance properties. This material is particularly suitable for handling abrasive and corrosive slurries, ensuring a longer service life for the pump.

The design of the metal casing may vary depending on the specific model and application of the slurry pump. For instance, some pumps may feature a single casing design, where the casing is directly exposed and secured with fastening devices. Others may have a dual casing design, where the inner casing is protected by an outer casing, with the primary fixation relying on the pressure exerted by the outer casing.

The metal casing of a slurry pump is crucial for maintaining the structural integrity of the pump and protecting the internal components from the harsh conditions of the slurry. It is designed to be robust and durable, capable of withstanding the high pressures and abrasive forces encountered during operation.

In summary, the metal casing of a slurry pump is a vital component that provides protection and structural support, ensuring the pump's efficiency and longevity in handling abrasive and corrosive slurries.

| pump parts |

| Item | Prod Code | Description | Net weight(kg) |

Adaptation type | Description |

| 1 | HPB1036R | Frame Plate Liner | 0.92 | 25HS-B Slurry Pump | natural rubber |

| 2 | HPB15036R | Frame Plate Liner | 1.13 | 40HS-B Slurry Pump | natural rubber |

| 3 | HPC2036R | Frame Plate Liner | 2.88 | 50HS-C Slurry Pump | natural rubber |

| 4 | HPD3036R | Frame Plate Liner | 5.32 | 50HHS-D Slurry Pump | natural rubber |

| 5 | HPE4036R | Frame Plate Liner | 9.80 | 75HHS-E Slurry Pump | natural rubber |

| 6 | HPF6036R | Frame Plate Liner | 26.00 | 100HS-F Slurry Pump | natural rubber |

| 7 | HPF8036R | Frame Plate Liner | 26.00 | 150HS-G Slurry Pump | natural rubber |

| ...... |

...... | Frame Plate Liner | ...... | ...... |

natural rubber |

| Details Images |

| Metal Chromium Alloy pump parts |

High-chromium wear-resistant cast iron KmTBCr26, High Chrome 26% has high hardness and heat treatment hardness of HRC58~62. It has good abrasion resistance. As for alkaline mixed liquid, it has good corrosion resistance and can be used in strong abrasion conditions. The casting process of high chromium cast iron is difficult and difficult to process. However, it has a long service life and moderate price, and is the most common material used for slurry pump.

High-chromium wear-resistant cast iron KmTBCr26, High Chrome 26% has high hardness and heat treatment hardness of HRC58~62. It has good abrasion resistance. As for alkaline mixed liquid, it has good corrosion resistance and can be used in strong abrasion conditions. The casting process of high chromium cast iron is difficult and difficult to process. However, it has a long service life and moderate price, and is the most common material used for slurry pump.

This alloy provides a great balance of hardness and toughness, making it effective to pump high abrasion and corrosive liquid.

It provides modest corrosion resistance pump components such as the impellers, casings, volute liners and throatbushes

Material Type: Erosion resistant white iron.

|

|

| Company Profile |

Shijiazhuang Heavy Pump Company Limited is changed by Hebei Xinda Slurry Company. We continue the fine tradition of producing slurry pumps-be famouse for its quality and service.

Shijiazhuang Heavy Pump Company Limited is changed by Hebei Xinda Slurry Company. We continue the fine tradition of producing slurry pumps-be famouse for its quality and service.

All products are mainly supplied to mining, metallurgy, public works, coal, petroleum, chemical, building material and other national economic deparments. The products are sold well all China and far to more than 40 countries in the world.

|

|

|

| Heavy pump products in five series: | We can choose the pump material according to pump working condition. |

| 1)Heavy horizontal slurry pump H series. | Heavy pump products advantage: |

| 2)Heavy vertical slurry pump SP ( semi-submersible pump). | 1)Anti-abraisive metal. |

| 3)Heavy dredge pump G series. | 2)Module design which makes the spareparts can be changed freely. |

| 4)Heavy gravel pump T series. | 3)Designed and built for long time with low maintenance. |

| 5)Heavy submersible pump. | Heavy Pump Company to the Customers: |

| Heavy Slurry Pump Material: | 1)Quality first. We guranteed every spareparts of the pump must be inspected closedly and will have our inspectors names on it. |

| a)Impeller: high-chromium alloy or rubber. | 2)Fast delivery at your requirement. |

| b)Volute liner: high-chromium alloy. |

|

| c)Shaft: 45# steel. |

|

| d)Shaft sleeve: ductile casting. |

|

| e)Frame plate: casting. | |

| f)Packing seal: Mechanical seal or Gland seal. |

| Production workshop corner |

|

| Enterprise production certificate |

| Customer Visit Photos |

| Packaging Transport Photos |

| FAQ |

Q: How can I make order online?

A: Send email or message(whatsApp/ wechat) us.you can ask any question ,after we confirm the detail, we can make order.

Q: Do you have MOQ limit?

A: The MOQ is 1 set.

Q: Which payments are acceptable?

A: T/T, L/C, Western Union, Paypal.

Q: Which shipping terms are available?

A: By sea, air, Express.

Q: How about the delivery time?

A: Delivery time is normally 3-7 working days after confirm the money. Depends on your quantity.

Q: What's your warranties?

A: 1 year after delivery.

Q: Can I buy parts separately?

A: Yes, all of the pump spare parts can buy separately.

| Similar Product Recommendations |

Message