edelook.com

edelook.com

150TL-315 Desulfurization pump

Shijiazhuang Heavy Pump Company Limited 1

Summary Description

1)Capacity: 310—410 m3/h

2)Head: 15—30 m

3)Speed(r/min): 1450r/min

$3000.00

PRODUCT DETAILS

Applications

|

TL FGD pump is single stage single suction horizontal centrifugal pump . It is mainly used as the circulating pump for absorbent tower in FGD appliances . It has such features : wide rang flowing capacity , high efficiency , high saving power . |

|

|

Properties Type Notation |

|

Technology Feature

■ It can change the impeller ' s position in pump casing by adjusting the bearing assemble to keep the pump working high efficiently all the time .

■ This kind of pump adopts back pull - out structure , keeping it easy construction and easy maintenance .

■ With extended coupling , impeller can be easily replaced without dismantling motor .

■ Two sets of taper roller bearing is fixed in the end of the pump , the column roller bearing is equipped at driving end . The bearing is lubricated by oil . All these can improve the bearing working condition and greatly enhance its life .

■ Mechanical sealing is adopted integrating mechanical sealing which is specialized in FGD technology to ensure its operation .

Material

This material has the corrosion resistance of duplex stainless steel 2205,2507 and the wear resistance of high chromium white cast iron in flue gas desulfurization process . Its perfor -mance is the same as A49 WARMAN .

Basic Parameters of Type TL pump

| Type | Flow(m3/h) | Head(m) | Speed(r/min) | Effciency(%) | NPSH(m) | Suction D/ Discharge D (mm/mm) |

| 100TL-315 | 70~150 | 11~30 | 1470 | 73 | 1.7 | 100/125 |

| 42~110 |

7.0~215 | 960 | 68 | 1.0 | ||

| 100TL-400 | 110~200 | 15~45 | 1470 | 72 | 1.8 | 100/125 |

| 55~130 | 10~22 | 960 | 70 | 1.0 | ||

| 125TL-400 | 200~370 | 22~45 | 1470 | 75 | 2.5 | 125/150 |

| 130~260 |

10~23 | 960 | 74.5 | 2.0 | ||

| 125TL-500 | 130~240 | 18~40 | 960 | 70 | 2.0 | 125/150 |

| 120~240 |

10~22 | 730 | 65 | 2.0 | ||

| 150TL-315 | 210~410 | 15~30 | 1450 | 75 | 2.5 | 150/150 |

| 110~250 |

6.5~13 | 960 | 72.5 | 0.5 | ||

| 150TL-500 | 160~320 | 12~40 | 960 | 73 | 2.0 | 150/150 |

| 140~290 |

8.5~22 | 730 | 73 | 1.0 | ||

| 200TL-400 | 300~580 | 22~50 | 1450 | 85 | 3.0 | 200/200 |

| 200~390 |

12~23 | 960 | 86 | 1.7 | ||

| 200TL-500 | 350~670 | 16~32 | 960 | 83 | 3.1 | 200/200 |

| 250TL-500 | 500~850 | 15~31 | 960 | 83 | 4.0 | 250/250 |

| 300TL-500 | 780~1340 | 16~32 | 960 | 84 | 5.5 | 300/300 |

| 350TL-500 | 1200~2100 | 12~30 | 960 | 88 | 6.0 | 350/350 |

| 400TL-500 | 1700~2600 | 15~26 | 960 | 83 | 3.1 | 400/400 |

| 500TL-630 | 2400~3850 | 22~37 | 960 | 85.5 | 7.0 | 500/500 |

| 2000~2920 |

13~22 | 730 | 85 | 6.5 |

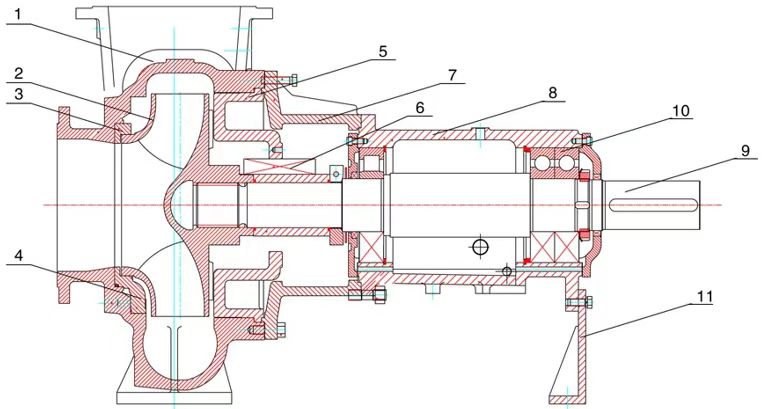

The Construction of TL FGD pump

| 1- Casing | 2- Impeller | 3- Casing ring | 4- Front cover |

| 5- Sealing box | 6- Mechanical seal | 7- Jointer | 8- Bearing bracket |

| 9- Shaft | 10- Bearing | 11- Support foot |

Material Selection

Mainte has developed a new kind of specialized anti - wear and anti - corrosive material which possesses the duplex stainless steel ' s anti - corrosive property and the high chrome white iron ' s anti -abrasive property in FGD process .

In the rubber pump casing , impeller , suction cover / cover plate are all made of specialized anti -wear and anti - corrosive material ; the material of front liner , back liner and back liner insert are natural rubber with light weight and natural , having excellent anti - corrosive property and low cost .

In metal pump casing , impeller , volute liner , suction plate and back plate are all made of specialized anti - wear and anti - corrosive material , the suction cover are made of ductile iron with rubber .

Main Parts  SHIJIAZHUANG HEAVY PUMP CO ., LTD

SHIJIAZHUANG HEAVY PUMP CO ., LTD

☎️ Tel:86-311-85883441

📧 E-mail: 419853905@qq.com

Website: www.heavypump.com

Add: No.39, Tanan Road, Shijiazhuang,Hebei,China (050024)

Technology Features

The pump wet parts are designed by advanced CFD Flowing Simulating Analysis Techniques to ensure its design reliable and its working effective .

The pump wet parts are designed by advanced CFD Flowing Simulating Analysis Techniques to ensure its design reliable and its working effective .

It can change the impeller ' s position in pump casing by adjusting the bearing assembly to keep the pump working high efficiently all the time .

This kind of pump adopts back pull - out struction , keeping it easy construction and easy maintenance . It doesn ' t need disassemble inlet & outlet pipeline .

Two sets of taper roller bearing is fixed in the end of the pump , the column roller bearing is equipped at driving end . The bearing is lubricated by oil . All these can improve the bearing working condition and greatly enhance its life .

Mechanical sealing is adopted integrating mechanical sealing which is specialized in FGD technology to ensure its operation .

Desulfurization pump Working Cases

Desulphurization pump is mainly used in flue gas desulphurization system, especially in wet desulphurization system of thermal power plant, Desulphurization pump is responsible for the flue gas containing sulfur dioxide and desulphurizing agent (such as limestone slurry) mixed to form desulphurization slurry, and through the circulation pump continuously circulating to the absorption tower, and flue gas full contact to complete the desulphurization reaction.

Enterprise production certificate

Business license

Customs Union EAC

Certification CE certification

ISO 9001 certificate

Customer Visit Photos

Visit and purchase products from South African customers

Visit and purchase products from Korean customers

From Russian customers for inspection and procurement of products

Visit and purchase products from Malaysia customers

Packaging Transport Photos

FAQ

Q: How can I make order online?

A: Send email or message(whatsApp/ wechat) us.you can ask any question ,after we confirm the detail, we can make order.

Q: Do you have MOQ limit?

A: The MOQ is 1 set.

Q: Which payments are acceptable?

A: T/T, L/C, Western Union, Paypal.

Q: Which shipping terms are available?

A: By sea, air, Express.

Q: How about the delivery time?

A: Delivery time is normally 3-7 working days after confirm the money. Depends on your quantity.

Q: What's your warranties?

A: 1 year after delivery.

Q: Can I buy parts separately?

A: Yes, all of the pump spare parts can buy separately.

Similar Product Recommendations

Message