edelook.com

edelook.com

DC-3N-5 Nitrogen making machine

Gaoyi Henglong Metal Crafts Co., Ltd.

Summary Description

1)Nitrogen purity (%): 99

2)Nitrogen production(Nm³/h): 2.2

3)power(w): 100

$3000.00

PRODUCT DETAILS

Nitrogen making machine Applications

| In coal mining industry, nitrogen machine is suitable for fire fighting, gas and gas dilution and other fields in coal mining. It has three specifications of ground fixed, ground mobile and underground mobile, which fully meet the nitrogen demand under different working conditions. In the rubber tire industry, nitrogen machine is suitable for nitrogen protection and molding in the process of rubber and tire production and vulcanization. It can also give nitrogen to automobile tires, prolong the service life of tires and reduce noise. In the oil and natural gas industry, nitrogen generator is suitable for nitrogen protection, transportation, coverage, replacement, rescue, maintenance, nitrogen injection and other fields in oil and natural gas exploitation. It has the characteristics of high safety, strong adaptability and continuous production. |

In metallurgical industry, nitrogen machines are suitable for heat treatment, bright annealing, protective heating, powder metallurgy, copper and aluminum processing, magnetic materials sintering, precious metal processing, bearing production and other fields. It has the characteristics of high purity and continuous production. Chemical industry, nitrogen making machine is suitable for petrochemical, Chemical industry of salt chemical industry, natural gas chemical industry, fine chemical industry, new material and its extension chemical process industry. Nitrogen is mainly used for covering, purging, replacing, washing, pressurizing, chemical reacting stirring, chemical fiber producing protection, nitrogen filled protection and so on. In the food industry, nitrogen machine is suitable for food green storage, food nitrogen packaging, vegetable preservation, wine packaging and preservation. |

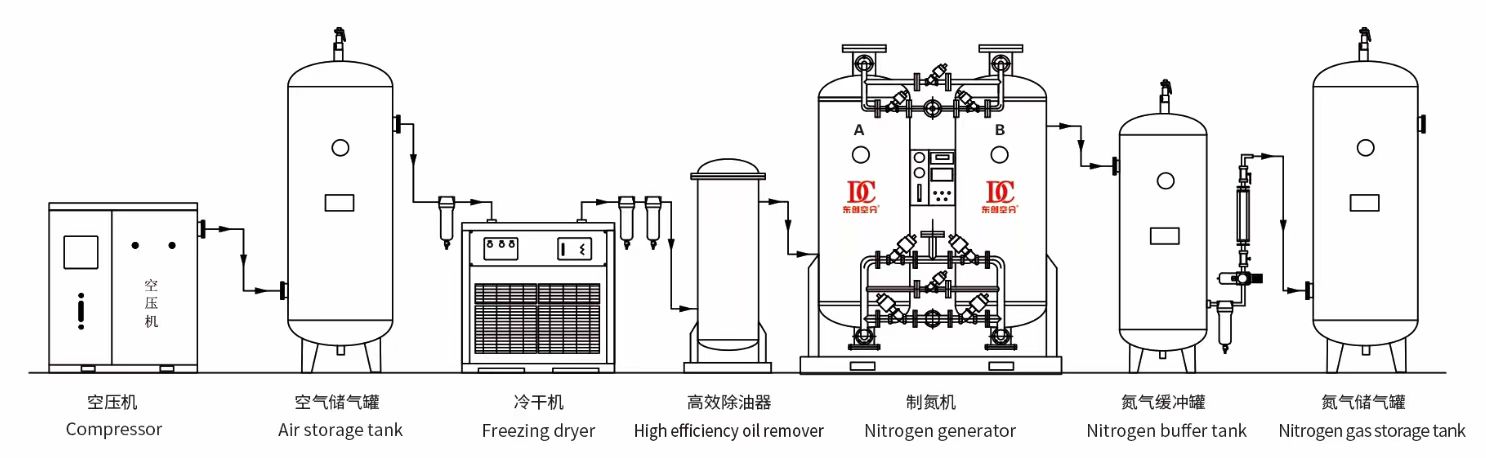

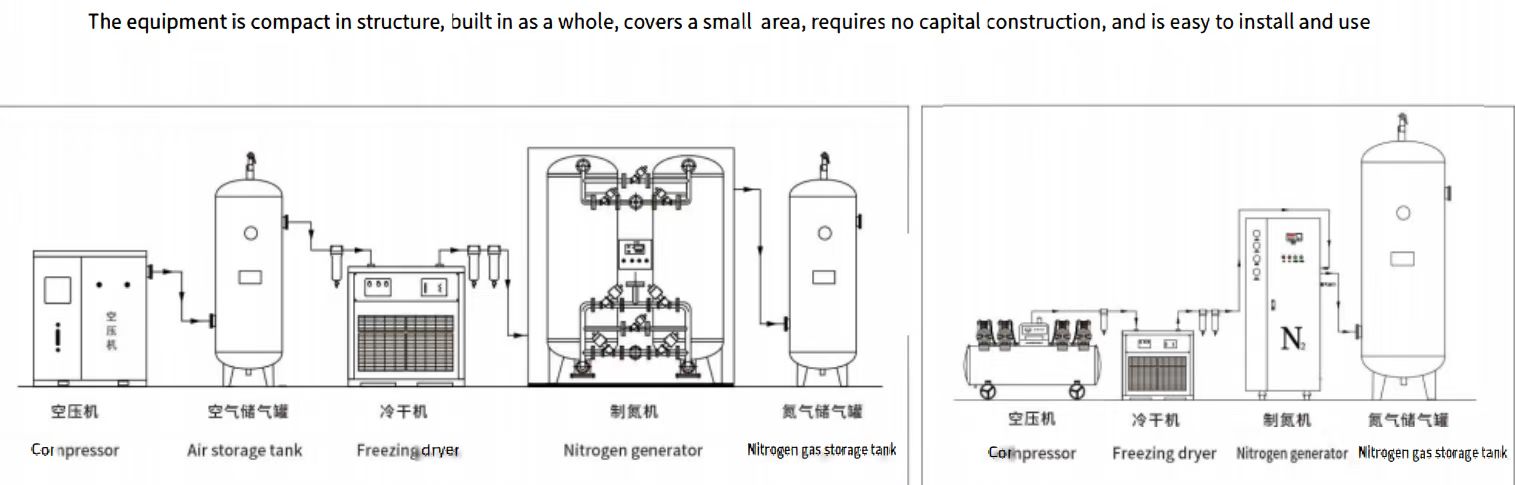

The whole nitrogen system consists of air compressor system, compressed air purification system, PSA adsorption nitrogen system, nitrogen buffer filtration system four parts The whole nitrogen system consists of air compressor system, compressed air purification system, PSA adsorption nitrogen system, nitrogen buffer filtration system four parts1, air pressure system The raw air is compressed to 0.8Mpa by the air compressor to provide power air source for the PSA nitrogen system. 2, compressed air purification components The treated compressed air enters the precision filter (set three-stage filtration in one) to remove most of the oil, water and dust, and enters the freeze dryer, and then enters the activated carbon filter, so that the oil content is ≤ 0.01ppm and the dust content is ≤ 0.01μm. |

3, air buffer tank, oxygen and nitrogen separation system The purified compressed air is fed into an air buffer tank, and then into two pressure swing adsorption separation systems filled with adsorbents, namely, the main machine of the nitrogen generator. Clean compressed air from the bottom of the adsorption tower into the air diffuser after diffusion, uniform into the adsorption tower, oxygen and nitrogen adsorption separation, and then outflow of nitrogen from the outlet. As a product exported from the top end and then entered the nitrogen buffer tank, pressure valve, flow meter output, the exhaust gas excretes this nitrogen production process at the silencer end, after which it is homogenized and depressed (to normal pressure), removes the adsorbed impurities (mainly oxygen), and completes the regeneration of the adsorbent. The two adsorption towers are operated alternately and circularly, continuously feeding raw air and continuously producing nitrogen gas. 4, nitrogen buffer system Finally, the nitrogen from the nitrogen generating unit is buffered by nitrogen buffer tank and dust fine filter to ensure that qualified nitrogen with stable parameters such as purity, output, pressure and dew point is produced. |

Nitrogen making machine Technology Feature

| Advantages of Dongchuang Nitrogen Production The traditional method of extracting nitrogen is to liquefy air and then distill it at a temperature of around -180 ° C.The process is very complex, and the total cost of nitrogen production is high. The PSA nitrogen machine can be operated under normal atmosphere, and its advantages are as follows: |

(1) Low production environment. (2) The process is simple, the equipment is small, the degree of automation is high, and the operation is convenient. (3) Quick start and easy to stop. The system can provide product gas up to 30 minutes after start-up and can also be operated intermittently. (4) Low working pressure, work safety, non-toxic, harmless and non-polluting. (5) Good flexibility. The purity and output of nitrogen can be easily adjusted. |

Reasonable design and convenient use

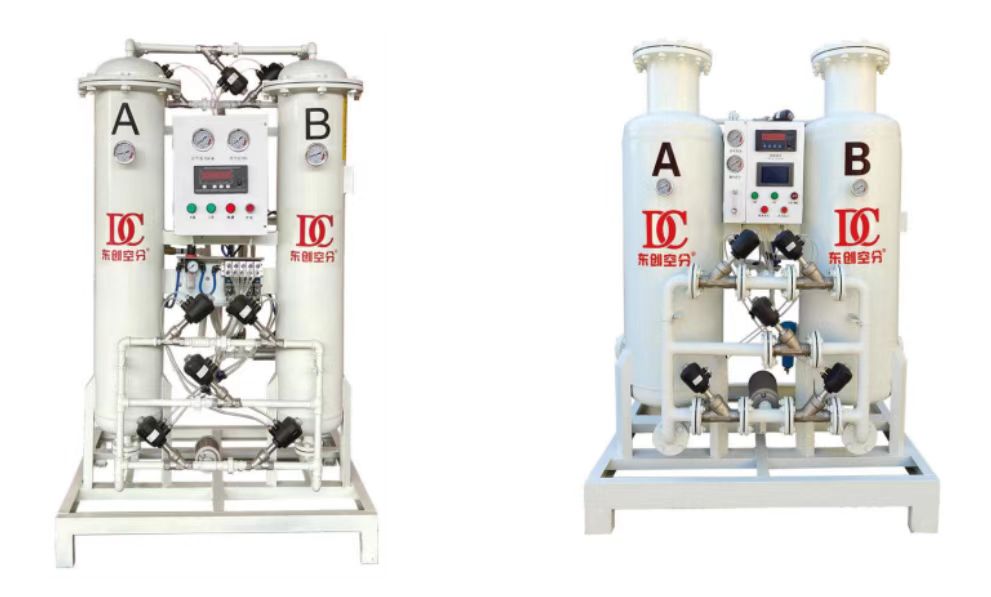

Nitrogen machine standard: adsorption tower A, adsorption tower B, activated carbon oil remover, nitrogen process tank, four-in-one, compact structure, transport, installation, operation and maintenance more convenient.

|

Equipment fully automatic operation |

|

High quality carbon molecular sieve |

Nitrogen making machine Parameters of Type

| model | Nitrogen purity (%) Nitrogen production(Nm³/h) | power(w) | size(mm) | ||||

| purity 99% | 99.5% | 99.9% | 99.99% | 99.999% | |||

| Air ratio 2.2 | 2.5 | 3.5 | 4.6 | 6.7 | |||

| DC-3N-5 | 13 | 11 | 7 | 5 | 3 | 100 | 950×750×1540 |

| DC-3N-10 | 18 | 15 | 10 | 7 | 4 | 100 | 1000×800×1550 |

| DC-3N-15 | 25 | 20 | 15 | 10 | 6 | 100 | 1150×900×1750 |

| DC-3N-20 | 35 | 30 | 20 | 13 | 8 | 100 | 1250×1000×1820 |

| DC-3N-30 | 55 | 45 | 30 | 20 | 12 | 100 | 1350×1000×1920 |

| DC-3N-40 | 70 | 60 | 40 | 25 | 15 | 100 | 1400×1260×2080 |

| DC-3N-50 | 90 | 80 | 50 | 30 | 20 | 100 | 1480×1300×2200 |

| DC-3N-60 | 110 | 95 | 60 | 40 | 25 | 100 | 1500×1400×2300 |

| DC-3N-70 | 125 | 110 | 70 | 45 | 30 | 100 | 1550×1450×2350 |

| DC-3N-80 | 145 | 125 | 80 | 55 | 33 | 100 | 1600×1550×2400 |

| DC-3N-90 | 165 | 140 | 90 | 60 | 35 | 100 | 2000×1900×2300 |

| DC-3N-100 | 185 | 160 | 100 | 65 | 40 | 100 | 2000×2000×2450 |

| DC-3N-200 | 350 | 300 | 200 | 135 | 80 | 100 | 3000×1500×2500 |

| DC-3N-300 | 550 | 450 | 300 | 200 | 120 | 100 | 3500×1700×2600 |

| DC-3N-500 | 900 | 800 | 500 | 340 | 200 | 100 | 4000×1800×2650 |

Enterprise production certificate

Business license

Customs Union EAC

Certification CE certification

ISO 9001 certificate

Customer Visit Photos

Visit and purchase products from South African customers

Visit and purchase products from Korean customers

From Russian customers for inspection and procurement of products

Visit and purchase products from Malaysia customers

Packaging Transport Photos

FAQ

Q: How can I make order online?

A: Send email or message(whatsApp/ wechat) us.you can ask any question ,after we confirm the detail, we can make order.

Q: Do you have MOQ limit?

A: The MOQ is 1 set.

Q: Which payments are acceptable?

A: T/T, L/C, Western Union, Paypal.

Q: Which shipping terms are available?

A: By sea, air, Express.

Q: How about the delivery time?

A: Delivery time is normally 3-7 working days after confirm the money. Depends on your quantity.

Q: What's your warranties?

A: 1 year after delivery.

Q: Can I buy parts separately?

A: Yes, all of the pump spare parts can buy separately.

Similar Product Recommendations

Gaoyi Henglong Metal Crafts Co., Ltd.

Gaoyi Henglong Metal Crafts Co., Ltd.

☎️ Tel:86-15097350308

📧 E-mail: 938274546@qq.com

Website: www.henglong.com

Add: Gaoyi County, Hebei city of Shijiazhuang Province, China

Message